Designing Better Patient Outcomes

Real Patients, Real Stories, Real lives

Created for you, and only you.

Our Philosophy, Designed for your life

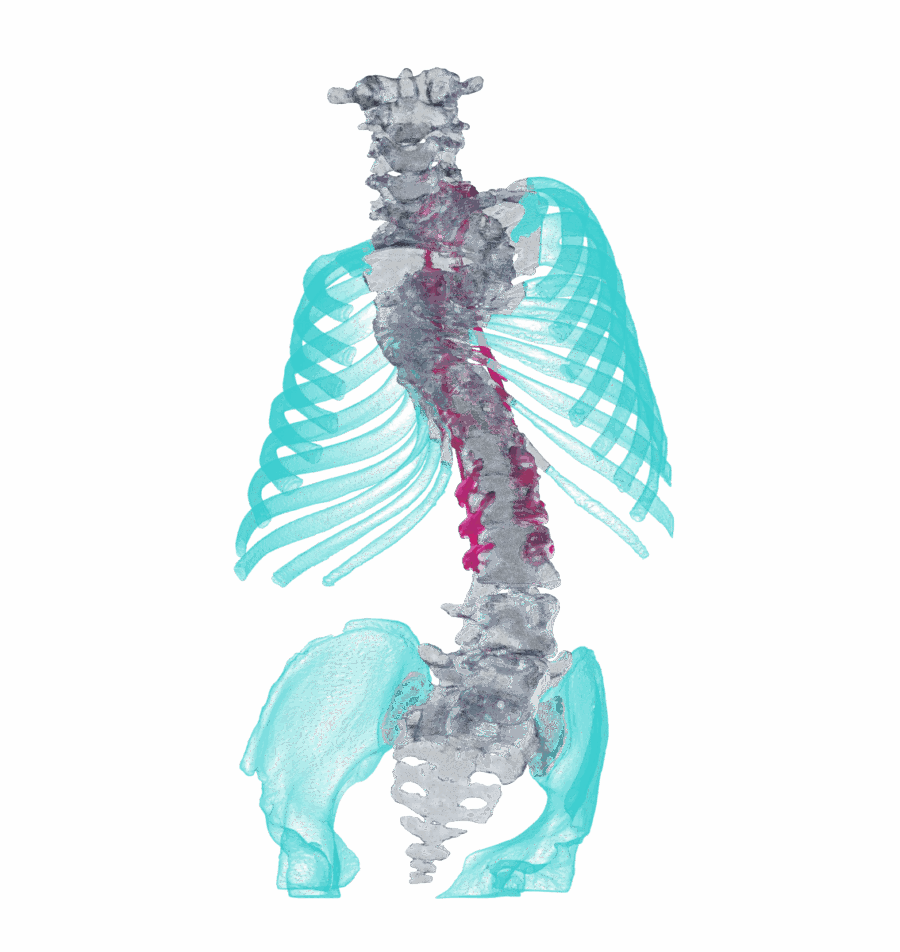

At MedCAD, we focus on what makes you unique — not just your body’s form, but how you want to live. Our engineering and design teams include technologists as well as artists trained in sculpting, product design, and 3D animation, and we craft every device to replicate, restore, and optimize your anatomy and activity level.

Designed with precision

To create a patient-specific MedCAD appliance, we capture 3D imaging from every angle at every possible extension. We develop a design that is fully tuned to your unique needs, then use 3D printing and multi-axis milling on leading-edge machines that are accurate to within microns.

designed for healing

We create precise guides so that every cut, every shave, every screw and attachment happens exactly where it should. Our patient-specific splints, guides, and models help surgeons do their best work, save time in the operating room, and can even reduce the number of necessary procedures.

We want you to forget us.

MedCAD creates devices matched to your unique situation — and designed for the way you want to live. We want our high-tech artistry to disappear completely into a new, healthier you.

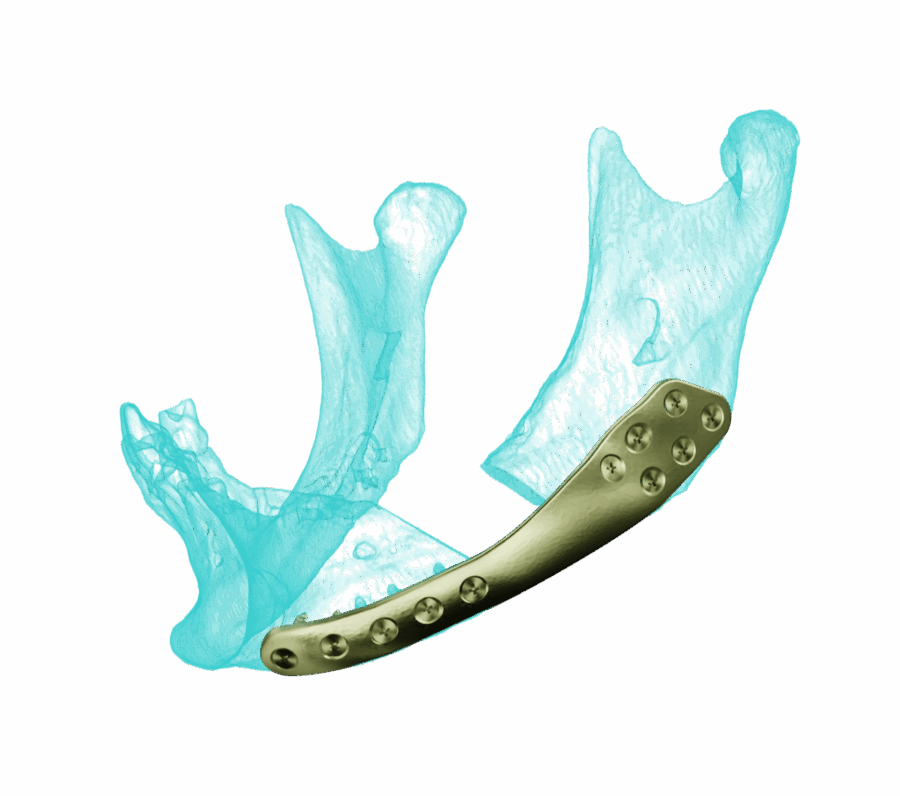

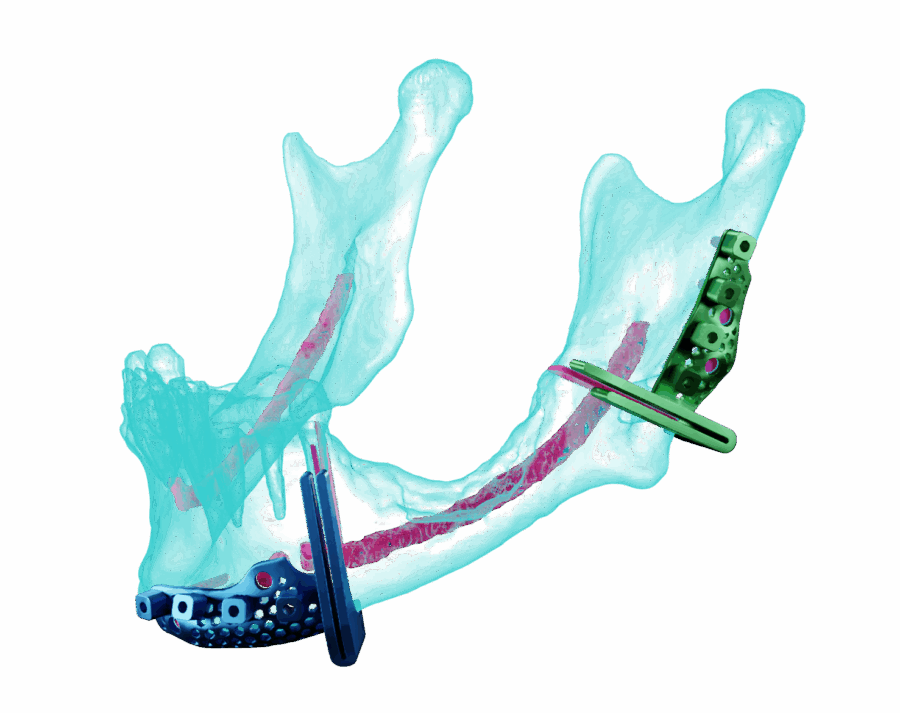

AccuPlan & AccuPlate

Comprehensive Surgical Planning and Personalized Plating Solutions

AccuPlan and AccuPlate work to optimize maxillofacial surgeries using detailed patient scan data and surgeon input. Our AccuPlan surgical planning uses 3D-CAD software to design custom guides, splints, and models, and AccuPlate delivers 3D printed titanium plates for a patient’s unique anatomy, customized for screw hole placement, thickness, and contour. Our advanced 3D printing allows for intricate designs that reduce mechanical stress and ensure precision in complex reconstructions.

AccuPlan & AccuPlate

Precision Planning and Personalized Surgical Solutions

Precise orthognathic surgeries start with AccuPlan surgical planning for custom splints, guides, and models designed with 3D-CAD software and a patient’s scan data. Our cutting-edge 3D printers create patient-matched AccuPlate implants in titanium, with surgeon-customized features including hole placement, thickness, and contour — optimizing the function and aesthetic outcome of corrective jaw procedures.

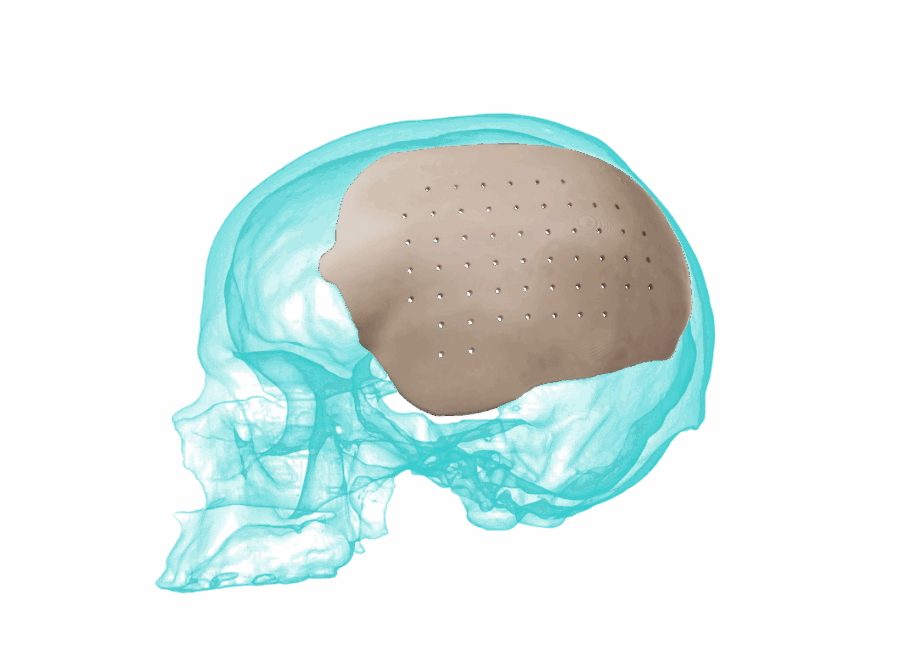

AccuShape PEEK & Titanium

Customized Implants for Precision Cranioplasty Solutions

MedCAD’s AccuShape Cranial Implants offer two material options - PEEK and 3D Printed Titanium - each tailored to fill cranial voids with precision and speed. Both materials are custom-designed based on detailed patient CT data, ensuring a perfect fit for conditions such as cranioplasty, temporal hollowing, and bone flap replacement.aAccuShape Cranial Implants in PEEK or 3D Printed Titanium are designed from detailed patient CT data for conditions including cranioplasty, temporal hollowing, and bone flap replacement. AccuShape PEEK closely matches the strength and characteristics of cortical bone for a biocompatible, radiolucent, and fast-delivery design. AccuShape Titanium uses a medical-grade titanium alloy for a robust, biocompatible solution. Either enables complex anatomical solutions with resolution contouring and no need for fixation plates, and are fully compatible with all approved neuro fixation screws.

AccuModel

Precision Visualization for Surgical Planning and Patient Education

AccuModel 3D-printed anatomical models turn patient CT data into high-definition, multicolor models to provide a tactile and visual representation of individual patient anatomy, allowing surgeons to visualize true-to-CT structures and simulated postoperative anatomy. As a standalone product or paired with one of our other solutions, AccuModel offers unparalleled accuracy and versatility for surgical planning and patient education.

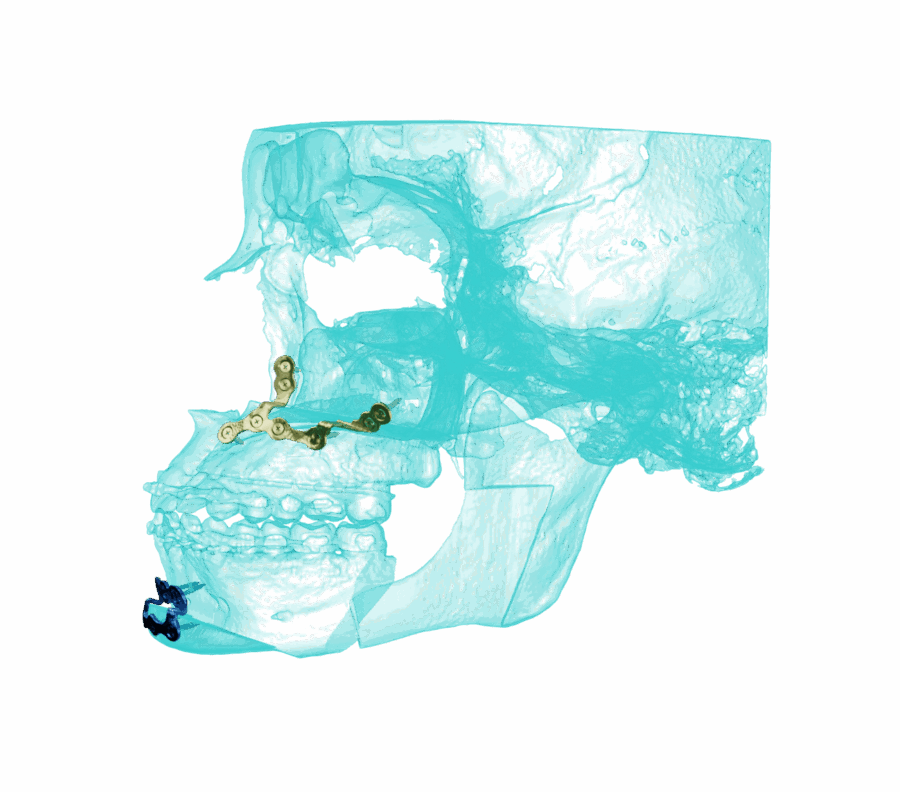

AccuPlan

Precision Surgical Guides, Dental Splints, and Surgical Models

MedCAD’s AccuPlan System is the cornerstone of patient-specific surgical planning for maxillofacial, orthognathic, cranial, and any other specialty. Using advanced 3D imaging and virtual surgical planning under a surgeon’s direction, AccuPlan delivers the most accurate, patient-specific solutions, ensuring each procedure is performed with clarity and precision. From the first step of planning to the final execution, AccuPlan enables surgeons to focus on achieving the best possible results for every patient, every time.

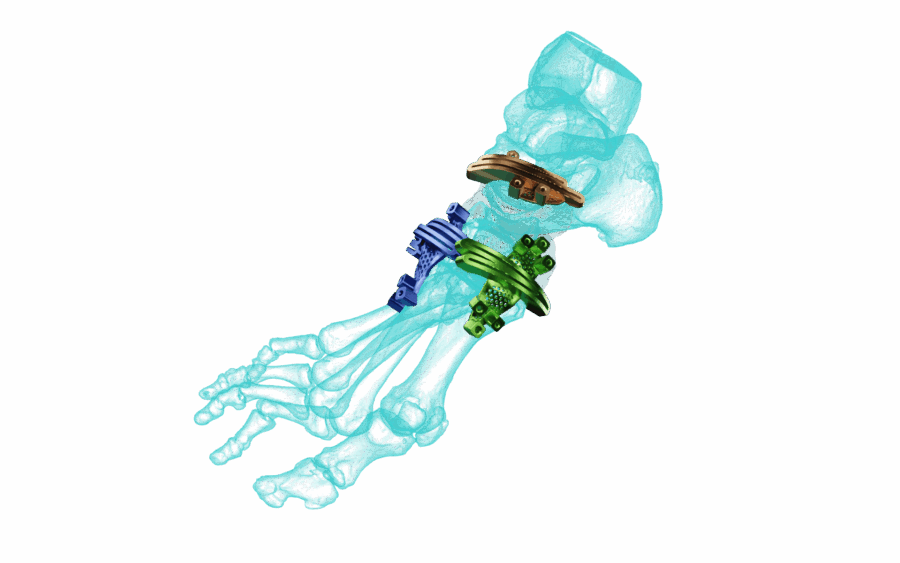

AccuStride® Foot + Ankle System

Patient-Matched Surgical Planning and Guide Solutions

The AccuStride Foot + Ankle System delivers patient-specific surgical guides and anatomical models designed to optimize complex foot and ankle procedures. Using detailed CT imaging and surgeon input, each case is custom engineered for precision, alignment, and efficiency. Ideal for procedures such as Lapidus, proximal phalanx and metatarsal arthroplasty, cavus foot correction, and Charcot reconstruction, AccuStride supports correction of multiple deformities in a single procedure. Guides are manufactured in UV-curable polymers or titanium alloy and can be delivered in as few as five business days.

Why Surgical Teams Use MedCAD

Proven & Approved

As pioneers in patient-matched implants, MedCAD has a history of FDA clearance in cranial, mandible, and orthognathic surgical products. Our dependable technology is now bringing innovative solutions to patients in need of foot and ankle care.

Surgeon-Led Design

Our dedicated design teams help surgeons implement creative approaches to difficult problems. With our thorough planning and design approach, multiple repairs and corrections can be made during a single procedure.

Greater Confidence

Our proprietary design process not only creates implants matched to patient needs, it allows surgical teams to plan procedures with complete anatomical information. Surgeons can consider and work through procedures virtually before deciding on the best approach.

Shortened Procedures

Because our implants are fine-tuned before a procedure even begins, they can be secured quickly and with minimal contouring or adjustments. Our precise surgical implementation guides mean less time on the table, creating lower costs for providers and quicker healing for patients.

Popular FAQ

Each surgical solution we create is 100% unique to the patient. We provide custom anatomical surgical solutions because we believe that each patient deserves the best possible outcome — one designed specifically for their unique anatomy and needs. We don’t just design pieces to fit into people’s bodies, we design products that help them reclaim their lives.

Everything we do starts with patient scan data, which gets converted into a 3D-CAD file. Then, with surgeon input, we design, manufacture and deliver the associated medical devices.

MedCAD’s manufacturing facilities are centrally located in Texas.